Sealoflex® SFB 5-20 (JR)

- Home

- Pages

- Team

Sealoflex® PMB for heavy duty asphalt

Climate changes, higher traffic volumes, heavier wheel loads. Today, many different factors limit the durability of asphalt pavements. The Sealoflex® SFB5 range of polymer modified binders has been specially designed to cope with such extreme loading cases. Sealoflex® SFB5 binders provide quality and durability unrivalled by any other kind of asphalt binder.

Sealoflex® SFB5 is an SBS polymer modified binder with relatively high polymer content. With the specially developed Sealoflex® processing technique the polymer is cross-linked and stabilised.

Accordingly asphalt mixtures with Sealoflex® SFB5 are rut resistant, crack resistant and almost impossible to fatigue even in extreme load cases which is confirmed by results in laboratories and in practice.

BROCHURE

Find out more about MILADCO Projects and what we can do for your business in our latest brochure. Simply fill out your details below and download your copy.

Sealoflex® SFB5 binders have

premium properties with respect to:

- Temperature susceptibility

- Elasticity and resistance to deformation

- Ductility and resistance to fatigue

- Ageing

- Adhesion promotion

Applications

- Airport runways, taxiways and aprons

- Port quay pavements

- Bridge decks

- Industrial pavements

- Container terminals

- Race tracks

- Trunk roads and truck lanes

- Porous asphalt and Stone Mastic asphalt

- Jet fuel resistant pavements

Benefits:

- Expect 50% to 300% increased pavement life

- Reduce pavement layer thickness

- Construction of pavement in asphalt, even in extreme load cases like container terminals

- Storage stable at high polymer content – improved storage life

Description of product

Sealoflex® SFB 5-20 (JR) is a high quality SBS-polymer modified bitumen for use in asphalt binder and wearing courses where increased resistance to fuels and oils is required (such as industrial areas, platforms and runways).

Product characteristics

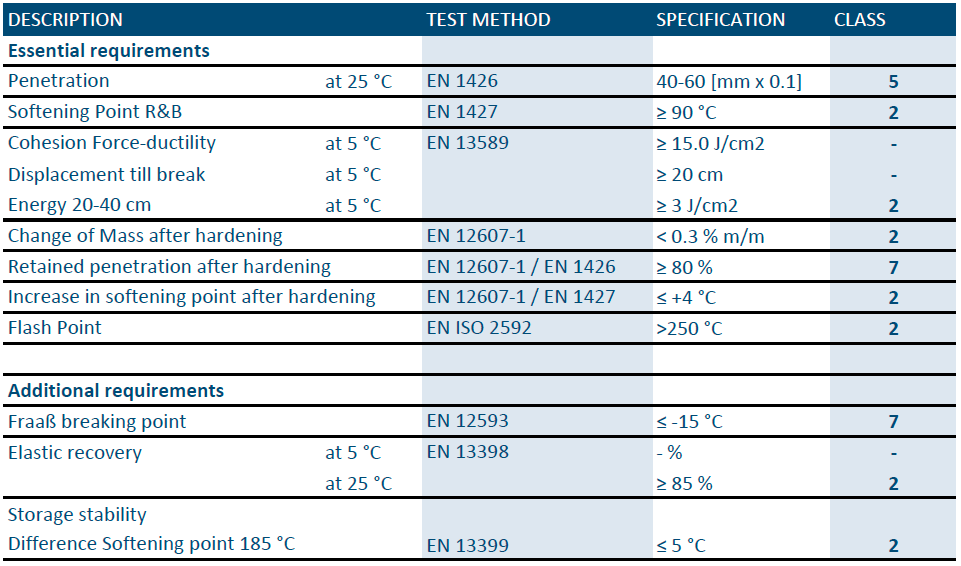

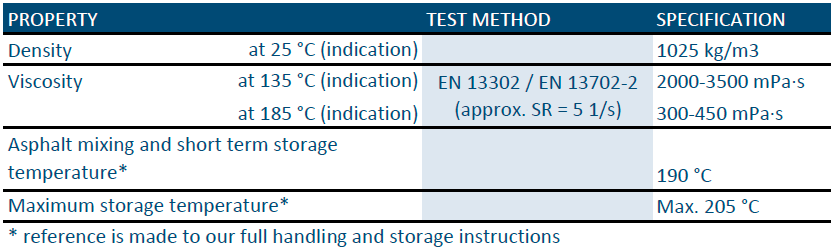

Sealoflex® SFB 5-20 (JR) polymer modified bitumen complies with European Standard EN14023:2010 and particular properties as summarized below.